rockwell c scale hardness test|rockwell hardness c scale chart : distribute • International (ISO)• US standard (ASTM International) See more 14 de fev. de 2024 · SlotsPlus Casino is an old Realtime Gaming-focused casino that has been around since 2010. New players can get an unfathomable 400% welcome bonus on their first deposit. Do not get your hopes up just yet, though. It is of utmost importance that you read this review first before jumping to any conclusions!

{plog:ftitle_list}

web战术训练. 注册. 免费获得评级,接收针对您的能力级别的问题,并跟踪您的进度通过统计数据和图表. 走出一步. a b c 天 e f g 时. a b c 天 e f g 时. 8 7 6 5 4 3 2 1.

The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). There are different scales, denoted by a single letter, that use different . See moreThe differential depth hardness measurement was conceived in 1908 by Viennese professor Paul Ludwik in his book Die Kegelprobe (crudely, "the cone test"). The differential-depth method . See moreThe Rockwell hardness test can be conducted on several various hardness testers. All testers, however, fall under one of three categories. Bench model hardness testers can be found . See moreThere are several alternative scales, the most commonly used being the "B" and "C" scales. Both express hardness as an arbitrary See more

• International (ISO)• US standard (ASTM International) See more• Brinell hardness test• Hardness comparison• Holger F. Struer• Knoop hardness test See more

• Video on the Rockwell hardness test• Hardness Conversion Chart• Rockwell to brinell conversion chart• Hardness Conversion Table See more

The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. You should obtain a copy of this standard, read and understand the standard completely before attempting a Rockwell test. Rockwell C to Brinell Hardness Conversion Chart. While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select .Rockwell Hardness Testing Reference Guide ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your .

These are a numeric number representing hardness, two letters “HR”, abbreviations representing “Rockwell hardness”, and the Rockwell scale designation, which shows the load applied on .This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges . The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell .The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the .

While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select the most suitable scale between Rockwell B (HRB) and Rockwell C (HRC). This article compares two types of Rockwell hardness to help you find the most ideal of the two for your hardness testing and conversion needs.

s is either 0.001 mm or 0.002 mm, depending on the Rockwell hardness scale used N is either 100 or 130, depending on the Rockwell hardness scale used Rockwell hardness testing with United Testing Systems. Some of our most popular test and inspect solutions that offer Rockwell hardness testing from United are: TRU-BLUE II Rockwell Hardness TesterScale C (carbide) testers are used for testing cemented carbides in the Rockwell A Scale, where tolerances of ± 0.20 of a Rockwell Hardness point are required. A specially selected “A” Brale penetrator is used to measure the hardness of cemented carbides in accordance with ASTM B 294 and the Cemented Carbide Producer’s Association (CCPA).Rockwell hardness test into what is today the most widely used method for acceptance testing and process control of metals and metal products. Since its development, the popularity of the Rockwell hardness test has steadily grown. The Rockwell hardness test continues to be applied as a tool forA widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .

No wonder, Rockwell hardness testing scales are globally used and are the most popular ones. It is used for static hardness testing of the material. We have described thoroughly in this article the scales of the hardness test. Just follow the standard scale tables and rules to get the accurate values of the hardness of your test material. The scale follows an even subdivision of 0.002 mm (2 µm), so that reaching half the reference depth also corresponds to half the maximum hardness value (Rockwell hardness value 50). When diamond cones are used, the Rockwell scale is .Find the hardness conversion for Rockwell C scale or high hardness range here. Download as PDF or get the Rockwell conversions right away. The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal .

What is the Rockwell Scale? Rockwell hardness testing is the most commonly used hardness testing method to measure the permanent depth of an indentation, which is finally compared to the Rockwell scale to derive the hardness number. . Hardness Conversion for Rockwell C Scale or High Hardness Range . In the case of Rockwell Scale, Hardness . The majority of applications are covered by the Rockwell C and B scales for testing steel, brass and other metals. However, the increasing use of materials other than steel and brass, as well as thin materials, necessitates a basic knowledge of the factors that must be considered in choosing the correct scale to ensure an accurate Rockwell test.

Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale.Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file.

Rockwell Hardness Testing File Sets . Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale. Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file.

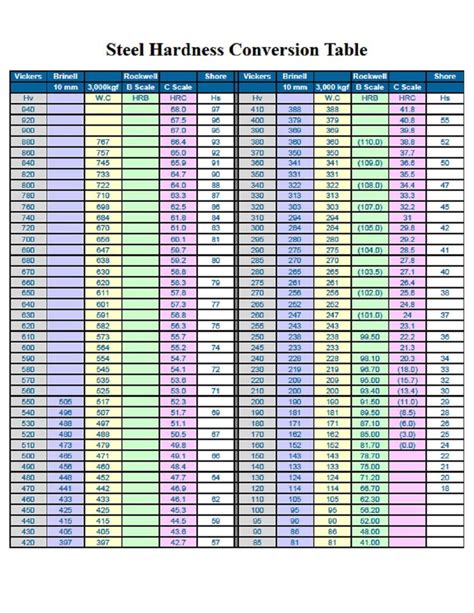

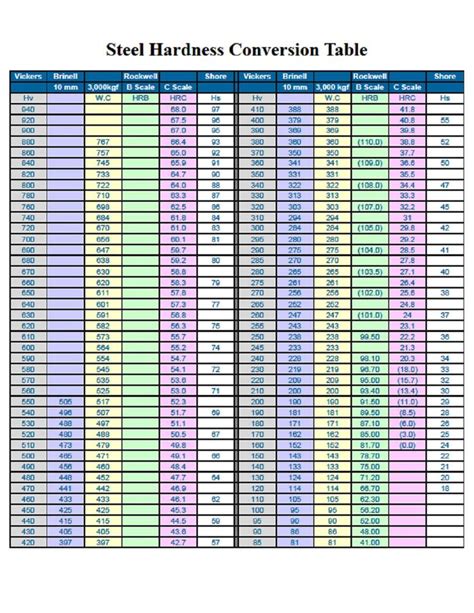

In conversion scales, common terms which should be first understood are scales, symbol, indenter and load or test force. All of these tables are based on these terms. For any hardness test, these tables are used for conversion of .

The Rockwell C hardness test is an industry-standard used to test the hardness of a material by measuring its resistance to indentation. The hardness of a material is commonly expressed using the Rockwell C scale (RC), which includes a series of 10 different hardnesses.Shop Rockwell C Scale, Hardness Calibration Test Block Set at MSC Direct top provider of high quality products. Starrett. Rockwell C Scale, Hardness Calibration Test Block Set-4 Piece. MSC # 83671750 Mfr # 67969. Write the first review. ,644.26. Price. Add to Cart Help. Help. 24/7 Customer Care. 1-800-645-7270;

Rockwell hardness test for plastics: In this test, a load of 15 or 30 kg is applied to the surface of the plastic material for a few seconds. . Rockwell C scale (RHC): This scale is used for testing hard materials, such as hardened steels and cemented carbides. The load applied is 150 kgf and the diamond cone indenter is used.

triaxial permeability soil testing

Steel Hardness conversion calculator: Brinell Hardness HB: Rockwell C - HRC: Rockwell B - HRB: Vickers - HV : Enter a figure into any of the fields and click calculate, the nearest values in each scale is shown, or zero if out of range. Values are approximate and for guidance only.Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics.The Rockwell test is particularly suitable for measuring the hardness of hardened metals and alloys. These materials often have high hardness levels and require higher applied loads to create an indentation. The Rockwell C scale (HRC) is commonly used for harder materials. Hardened Materials The Rockwell hardness test is less affected by .The Rockwell C test is performed with a Brale penetrator (120°diamond cone) and a major load of 150kg. Each Rockwell hardness scale is identified by a letter designation indicative of the indenter type and the major and minor loads used for the test. The Rockwell hardness number is expressed as a combination of the measured numerical hardness .

rockwell steel hardness chart

Basic principle and practical procedure of the Rockwell hardness test - Testing machine, test piece, conical diamond indenter - Basic principle, hardness d. In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation.A Rockwell hardness testing machine that is designed to be transported, carried, set up, and operated by the users, and that measures Rockwell hardness by the Rockwell indentation hardness test principle. Rockwell hardness machine. A machine capable of performing a Rockwell hardness test and/or a Rockwell superficial hardness test and . The combination of indenter and test force make up the Rockwell scale. These combinations make up 30 different scales and are expressed as the actual hardness number followed by the letters HR and then the respective scale. A recorded hardness number of 63HRC signifies a hardness of 63 on the Rockwell C scale.

rockwell hardness material chart

webTiki Wonders slot is a five-reel, thirty-line video slot game from Netent. Those who opt to play the Tiki Wonders slot machine have a chance to win two progressive jackpots, triple prizes in free spins rounds and more. There are many colourful symbols on the slot reels, including low-paying and high-paying ones.

rockwell c scale hardness test|rockwell hardness c scale chart